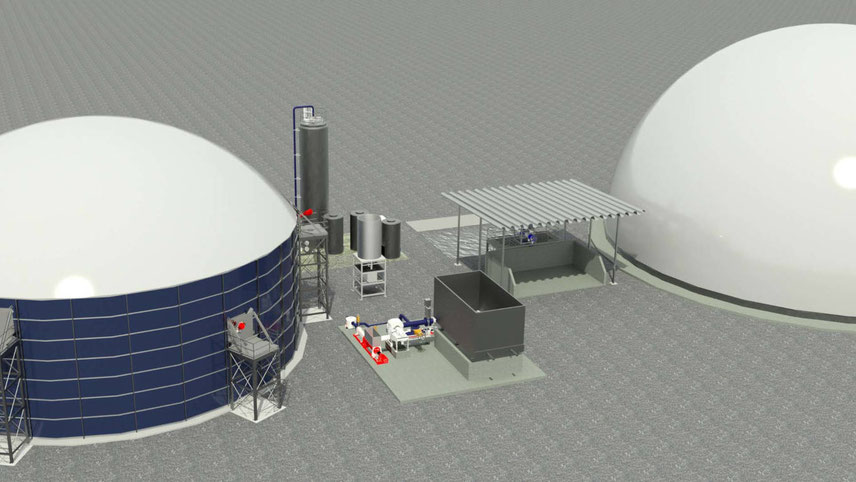

Mohali-based Pritika group, which is celebrating its golden jubilee this year, has adopted the strategy of expanding geographically to meet the high demand in the international markets. The group’s two flagship companies, Pritika Auto Industries and Pritika Engineering Components, have Pritika Industries and Meeta Castings as companions. With five manufacturing facilities in North India, the Pritika group, which caters to leading original equipment manufacturers (OEMs) of tractors and commercial vehicles across India, has export operations in the US for material handling applications. The group offers various products, including axle housings, wheel housings, hydraulic lift housings, cylinder blocks, crankcases and more. “We are investing in advanced technology and have expanded manufacturing capabilities to meet the automotive industry’s evolving demands,” affirms Harpreet Singh Nibber, CMD, Pritika group. “We also remain optimistic about its growing product portfolio, including value-added products and are exploring opportunities in the railways and defence sectors.” The group aims to become the largest manufacturer of machined castings, while becoming the preferred choice for OEMs. It plans to increase its installed capacity to 100,000 tonnes by 2027 from its present capacity of 75,000 tonnes plus per annum (tpa). Preferred choice Started in 1974, Pritika group was promoted by the late Raminder S. Nibber. The group specialises in the manufacture of machined castings and automotive components, with manufacturing facilities situated at Mohali, Derabassi Hoshiarpur (Punjab) and Tahliwal (Himachal Pradesh). With strategically located plants near key OEMs, the group is the only major tractor component-maker in the nearby region. It has set its sights high, aiming to become one of the largest producers of machined castings in the country. It also aims to be the preferred choice among OEMs for machined castings. The group is one of the most prominent component suppliers in the machined castings segment, catering primarily to tractors and commercial vehicles. The group makes a wide range of products, such as axle housings, wheel housings, hydraulic lift housings, end covers, plate differential carriers, brake housings, cylinder blocks and crank-cases. Pritika is one of the most prominent component suppliers in the tractor segment of the automobile industry in the country and supplies to OEMs, such as Mahindra & Mahindra, Swaraj Engines, Escorts Kubota, TAFE, Brakes India, CNH (New Holland Tractors), International Tractors (Sonalika), Ashok Leyland and IBCC (USA). Expanding its portfolio with higher-margin products, the group aligns itself with technological advancements and higher-value offerings. "We are investing in advanced technologies and expanding our manufacturing capabilities to meet the evolving needs of the automotive industry,” elaborates Nibber. “With an expanding product basket that includes value-added products, we are poised for significant growth. We are optimistic about opportunities in railways and the defence sector and are actively developing products for these markets. Our goal is to become the largest manufacturer of machined castings and the preferred choice for OEMs." Demerger to boost growth The National Company Law Tribunal, Chandigarh bench, has approved Pritika Industries' demerger, separating its automotive, tractor and engineering components business into Pritika Auto Industries. The demerger allows Pritika Auto Industries to expand its operations, encompassing both castings and machining, which is expected to improve margins. Pritika Industries, specialising in machining operations, is wholly owned by the promoter family. The demerger is expected to streamline operations and boost business growth.

-

Pritika group aims to become one of the largest producers of machined castings in the country