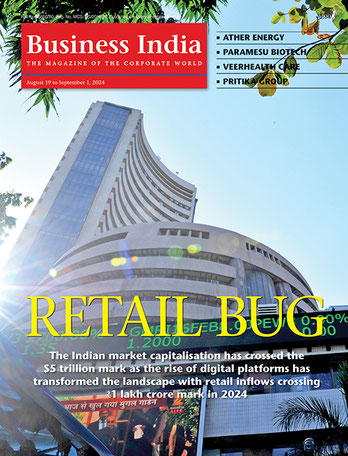

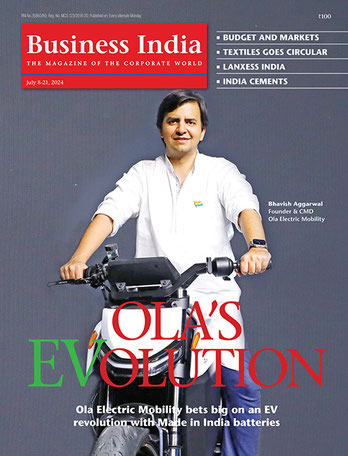

At a recent public event in Nagpur held to introduce a new family electric scooter, Rizta, the Bengaluru-based Ather Energy’s co-founder and technology head, Swapnil Jain, said: “The Indian electric two-wheeler is better than any electric two-wheeler in the world.” Understandable hyperbole? Maybe, maybe not. Some 11 years ago, Jain and his IIT Madras batchmate Tarun Mehta set up Ather Energy to build an electric scooter best suited for India, given the diverse weather and road conditions across the country. The duo’s original plan was to make batteries for other electric vehicle (EV) makers, which fortunately evolved into full-fledged vehicle manufacturing or OEM. By February 2016, the company’s first electric scooter, the S340, was unveiled at the Surge conference in Bengaluru. Choosing one of the most important tech conferences in the country to unveil its first product must have been a big giveaway on what Ather’s founders thought about their product. The S340 was not just another electric scooter that one could simply plug, charge, and ride. It also had some industry-first features like a touchscreen dashboard, on-board navigation, fast-charging for electric two-wheelers, reverse mode, and a mobile app. The new kid on the block came packing some serious technology and features that Indian two-wheeler commuters had not expected to see on their scooters or motorcycles. Since then, Ather has launched six models, including its latest family electric scooter, Rizta, deliveries of which have just started. Its earlier 450 series and the more recent Apex are also loaded with features that come directly from Ather’s R&D Centre, which houses a third of its entire workforce, including those in its plant in Hosur, Tamil Nadu. T his is a unique feature in India’s automobile sector. Ather is an R&D-driven company that files more patent applications than most start-ups and an extraordinary number compared to other auto companies that are several times Ather’s size and have been around for several decades. Ather, which is just around a decade old, has filed 241 patents in India and five others internationally. Sector took off Since the automobile sector took off in India in the 1980s on the back of a handful of joint ventures (Japanese, American, and South Korean), the industry has come a long way in terms of the range of products and volume it delivers not just in the domestic market, but globally too. Many of the marquee brands in the country have a big chunk of their sales coming from overseas. Last year, around 24 million vehicles were sold locally, while another 4.5 million were exported. Many OEMs have made India the production base for the global market because the factors of production are still relatively cheaper here. But we still do not have a designed and made-in-India automobile that has a big global appeal, like a Toyota Corolla or a Volkswagen Beetle. Ather not only sees this as an oddity but is also convinced this can be corrected. Jain and Mehta have spent over a decade building a culture and team that stand out in an industry that has been focusing more on mass production of scores of new vehicles launched every year. Ather’s big idea, however, is to focus on R&D, get the best engineers, and challenge them to deliver better-than-industry outcomes on all key metrics – performance, safety, and comfort – while still keeping costs under control.

-

Ather’s goal is to design and make very smart electric scooters that are best suited for India