-

Sarkar: demand has come back

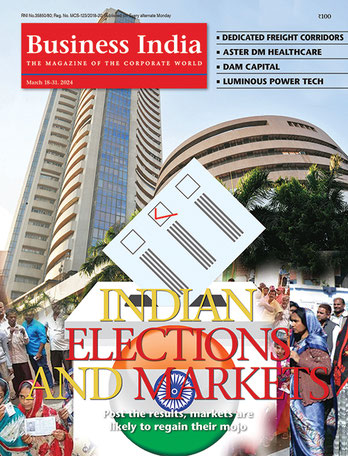

Not surprisingly, share prices of all the steel companies are moving upwards. Tata Steel hit a new 52-week high of Rs850 on 1 April. Though the 52-week low of Rs251 may not be a realistic benchmark for comparison, the shares three years ago were priced at Rs540. Currently, it has a market cap of Rs.1.1 lakh crore.

The shares of JSW, which became the largest company by capacity in India after the announcement of its new 5 million tpa plant at Dolvi, have moved up from Rs293 on 1 April 2019 and are now trading at Rs509, with a market cap of Rs1.21 lakh crore. The shares of Steel Authority of India, which is working towards becoming a 50 million tpa by 2030, have also seen prices moving up to a 52-week high of Rs82 on 1 April 2021. The shares of Jindal Steel & Power have moved up too.

Like steel, there are several other sectors, which have profited from the rising commodity prices. Hindalco Industries has gone up by nearly 4x to Rs348 in the last one year. It was Rs210 on 1 April 2019. Hindustan Copper has gone up by nearly 8x, while Hindustan Zinc has doubled in a year.

The rising commodity costs have caused all-round consternation amongst user industries, stoking fears of an all-round price-hike across products – especially with the demand likely to remain robust, following the economy in recovery mode. One can also see better demand translating into higher volume growth. But will the companies be able to pass on the full input costs rise?

“Many companies, especially the large ones, with pricing power, will be able to pass on a significant portion of the costs. Demand has already come back to pre-Covid levels. Volume growth, as also savings effected on streamlining operations and bringing in more efficiencies, will also help in offsetting the costs. Profit will be normal in 2021-22,” says Aniruddha Sarkar, CIO & portfolio manager, Quest Investment Advisors, a Mumbai-based fund management company. “The main concern will be how much the input costs really stoke inflation,” he adds.

In the case of automobiles, most majors, including Maruti Udyog, Tata Motors, Datsun, Ford and Nissan, have all indicated price hikes from 1 April. Ford has indicated a 3 per cent rise, while Maruti will be raising prices by 1-6 per cent (Rs5,000-34,000). Tata Motors had already effected one increase in January this year. Others are likely to follow. Many auto companies are also exporting in a big way.

“With global recovery in place, many exporters will price their products higher in global markets and try to subsidise the domestic markets, given the high level of competitiveness prevailing across sectors,” says Deven Choksey, MD, KR Choksey Investment Managers. “Otherwise, margins may come under pressure in some industries which do not have a strict pass-through mechanism,” he says.

-

Choksey: higher price for export markets

In the case of good brands, consumers may be willing to pay a little more. Companies in the FMCG and food sector will be able to raise prices. Hindustan Unilever, Marico, Nestle, Britannia and ITC may get away with a small hike. Raw material costs, as a percentage of sales in their case, is anyway smaller. In the case of Nestle, the raw material cost is 41 per cent of sales; in the case of HUL, it is 47 per cent; and, for ITC, it is just 39 per cent. Known brands in the paint industry, such as Asian Paints, Kansai Nerolac or Berger will also be able to pass on costs.

In plastic equipment, a few big companies like Finolex Cables, Astral Pipes and Supreme may be able to do it – this is also the case with electric goods manufacturing units in the organised sector, such as Havells, Bajaj, Crompton or Orient. These companies would be hurt by the rise in the price of copper, aluminium as also PVC.

The fact is that “the sharp rise in input costs has impacted a lot of companies across industries”, says Sachin Bhartiya, partner, Light House Funds. “A few of the companies in our portfolio have been able to neutralise the impact by increasing the product prices but, smaller companies, who do not have such pricing muscles, have been badly hit and their margins have come under tremendous pressure.” Light House Funds, a private equity financier, has till date invested $5-20 million across 20 companies.

The most vulnerable

For many end-users, however, the rising input costs have not been well taken. In fact, the hardest hit has been the MSME sector, which typically uses these metals as raw materials to provide inputs to end manufacturers of goods. In many cases, where government projects mandate tenders exclusively for MSMEs, these units are facing a mammoth challenge – especially, as these tenders do not have any scope for escalation in prices. With prices changing virtually every week, no one is able to do business, being afraid of being caught at the wrong end of the cycle.

“Raw material costs have gone up significantly, says Jaydeep Modi, president, Federation of Small-scale Industries, Vadodara, representing 700-plus units in and around the city. “As against the normal 2-3 per cent rise, if the costs go up by 40-50 per cent, as they have in steel, we will be hit badly. We are unable to pass on the rising costs to customers. In the case of government tenders, if the work is not completed, units tend to get blacklisted. Survival is at stake for many units.” Besides cost, supply is also an issue, says Modi, as suppliers are unwilling to lock in rates for even a week, let alone a month. It is not possible to get new orders, if rates are not frozen.

-

Modi: raw material costs have gone up

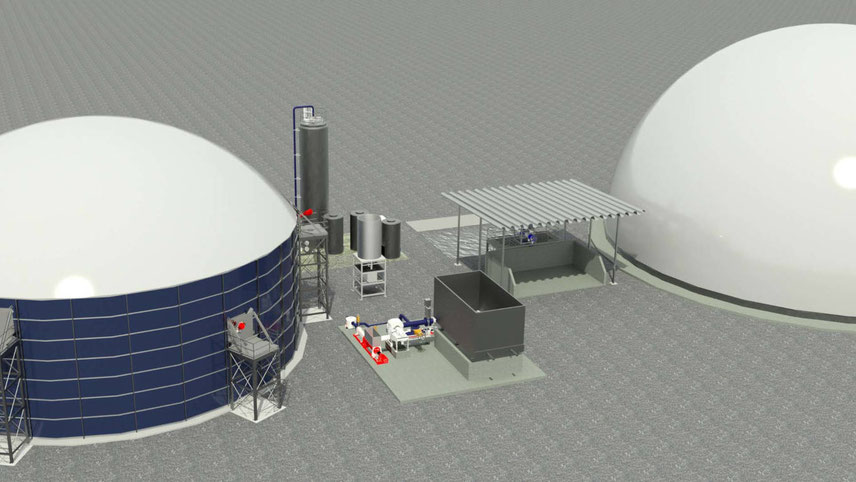

Polymers and specialty chemicals are some of the other industries which are riding the commodity cycle. Besides, PSUs like ONGC, GAIL, Reliance Industries, MRPL and Haldia Petrochemicals (not listed) are also reaping the benefits. “In the case of polymers, it is even worse,” says Arvind Mehta, chairman, governing council, All India Plastic Manufacturers Association, representing more than 20,000 plastic processing units, besides other associations.

The prices of plastic, PP, HDPE, PP and LDPE have shot up considerably in the last six months.” He explains that export markets are quite robust and demand is high. Large producers get a price in the export market, which is better than the domestic market, and the supply is limited. “Besides high prices, many MSMEs have limited bank finance. It is difficult to arrange top-up loans and, even if one does, interest has to be factored in.”

Mehta says that many units find it unviable and prefer not to do business. As a result, many units are running at 50 per cent capacity or even less. Employees are also a casualty, as units cannot indefinitely support them. It is estimated that roughly five million persons are employed in the industry.

In the case of construction companies, it will be difficult for them to pass on costs, as several developers have already tried to sell their units before completion. Large construction companies like L&T do not take material costs on their books and leave this to the clients. For them, it is a pass-through cost. But, in the case of several smaller contractors, who have taken on government contracts, it would be difficult to offset higher input costs.

The only saving grace for several companies is that the cost savings during the pandemic will help them to sail through this year. Costs saved on travel, infrastructure, administration and the lower interest rates will help them neutralise, to some extent, the increased input costs. Many companies, which tended to make better than normal profits may well have to do with normal profits in 2021-22.