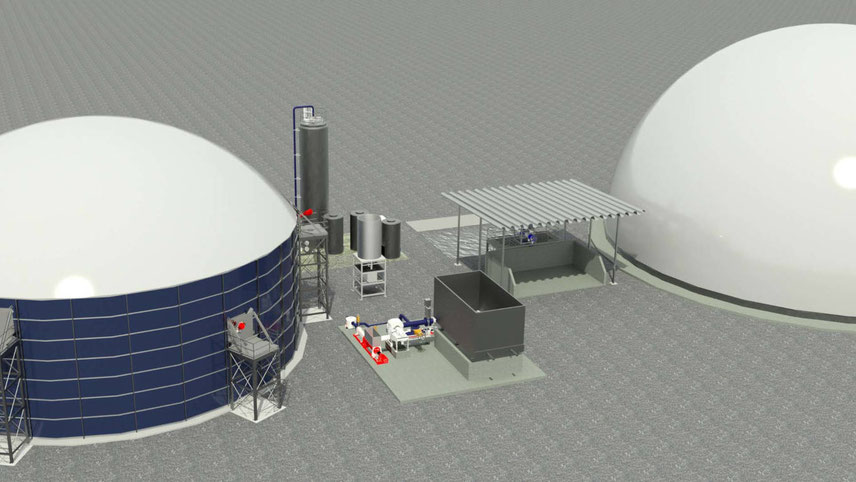

Ratnaveer Precision Engineering Limited (RPEL), based in Gujarat, is transforming its low-commodity stainless-steel business into a high-value niche product through backward integration. Established in 2002, RPEL makes a wide range of stainless-steel products, including washers, pipes, tubes, sheets and solar mounting hooks. The company produces over 2,500 washers of different sizes and international standards. Founded by Ramanand Sanghvi, RPEL is under the management of Vijay Ramanlal Sanghvi and his family. In recent years, RPEL has prioritised the synergistic system of backward integration, where it recycles the steel waste generated during manufacturing its products and transforms it back into raw material for further use in manufacturing. The company operates four manufacturing units – two located in Vadodara, one in Waghodia (near Vadodara), and another one in Ahmedabad. By backward integration of stainless-steel sheets, washers and solar hooks, the company has effectively reduced its production costs. RPEL’s manufacturing Unit I and Unit II are specifically dedicated to producing goods for sale, while Unit III and Unit IV focus on processing manufacturing by-products and converting them back into raw materials. This unique integration strategy not only strengthens the company but also maximises its return on investments compared to its competitors. About 11 per cent of raw materials are generated through backward integration, with the remaining 89 per cent being procured from external suppliers. Avinash Gorakshakar, head, research, Profitmart Securities, highlights the significance of RPEL’s backward integration model, stating that it significantly amplifies the company’s investment returns. RPEL’s products have a wide range of applications, including automotive, solar power, wind energy, power plants, railways, oil & gas, pharmaceuticals, sanitary & plumbing, instrumentation, electromechanics, interior design, building & construction, electrical appliances, transportation, kitchen appliances, chimney liners and other industries. Innovative approach The company’s seamless backward integration process, which transforms metal scrap into high-quality finished products, sets sustainable manufacturing benchmarks. This innovative approach not only enhances efficiency, but also underscores the company’s commitment to environmental sustainability. RPEL has also ventured into producing electro-polished tubes for the dairy and pharmaceutical sectors, demonstrating its adaptability and versatility. With an in-house design team, RPEL ensures that each product is a meticulous blend of form and function, setting unparalleled standards in precision engineering. Moreover, RPEL is dedicated to meeting orders from ISRO and HAL, ensuring that all pipes adhere to stringent ASTM standards, guaranteeing their reliability and durability in military and aerospace operations. A milestone in RPEL’s growth trajectory was the announcement of a capital expenditure plan of Rs106 crore for capacity expansion in the current fiscal year. The first tranche of Rs45 crore has already been allocated, marking a bold testament to the company’s growth ambitions. This strategic move focusses on tapping into opportunities within the Indian defence sector. “Our focus on innovation and quality has driven our success and this investment reaffirms our commitment to providing superior products and services,” elaborates Vijay Sanghvi, managing director, RPEL. “Our pipes, designed to withstand corrosive and stressful environments, will support vital installations in the Indian Navy, ISRO, and HAL projects. Furthermore, we aim to supply stainless steel pipes to the Indian Navy, Army, and Air Force, ensuring optimal performance in critical applications such as engines, boilers, and air defence installations”.

-

RPEL produces over 2,500 washers of different sizes and international standards