Q What qualifies as green steel?

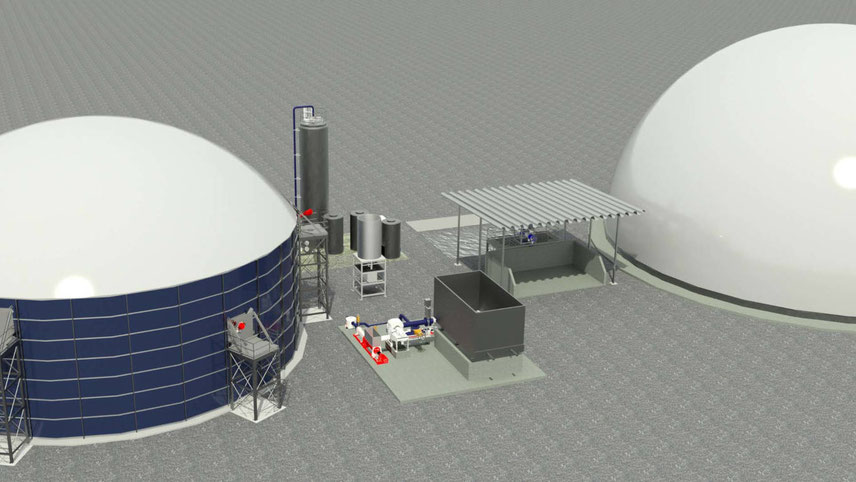

A There is no official definition for what qualifies as green steel; so multiple companies refer to what they produce or plan to produce as green steel. There are companies that are using electric arc furnaces to recycle steel and use green energy if it is available in the grid and call it green steel. There are companies which are developing hydrogen as a substitute for coal as a reductant in the steel making process. But making hydrogen is also energy intensive and so the source of energy in the grid needs to be green. While currently there are a lot of plans, there is not much actual production of ‘green’ steel in the market. As of now even if it is produced, it will be more expensive than the conventional routes and so either governments or customers have to support this initiative to make it financially viable.

Q Is it possible to use liquid hydrogen instead of coking coal?

A Hydrogen (more as a gas than a liquid) can be used as a substitute for coking coal as coking coal is not just a source of energy but a reductant. You could either work on injecting hydrogen in the blast furnaces and reduce the consumption of coke and hence reduce the carbon footprint of the process or you could use hydrogen to substitute gas in gas-based DRI production and use that in an electric arc furnace along with steel scrap to produce green or greener steel. But the challenge is production of hydrogen which is energy intensive and therefore the source of energy for hydrogen production needs to be green. Otherwise, the hydrogen produced is not called green hydrogen and is called blue or grey hydrogen and hence one is not fully solving the problem. Also, you need a lot of hydrogen to substitute the coal used in the steel industry currently and it needs to be available at competitive prices. We are some years away from all this.

-

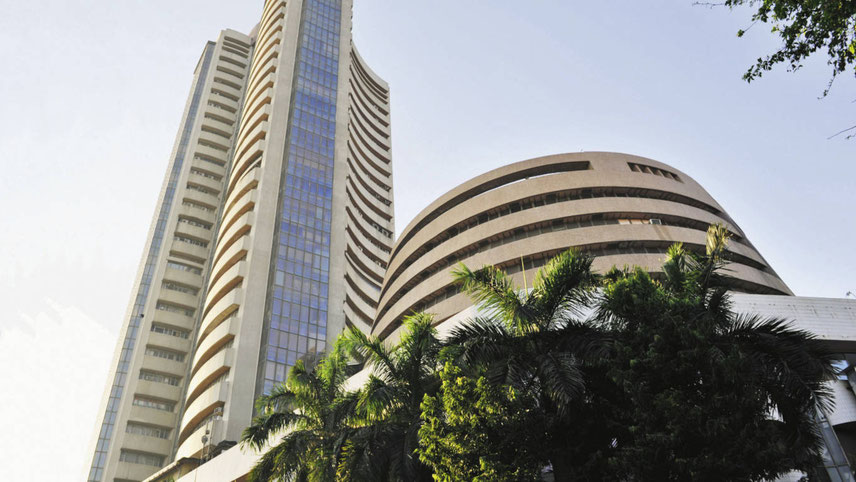

T.V. Narendran, Tata Steel