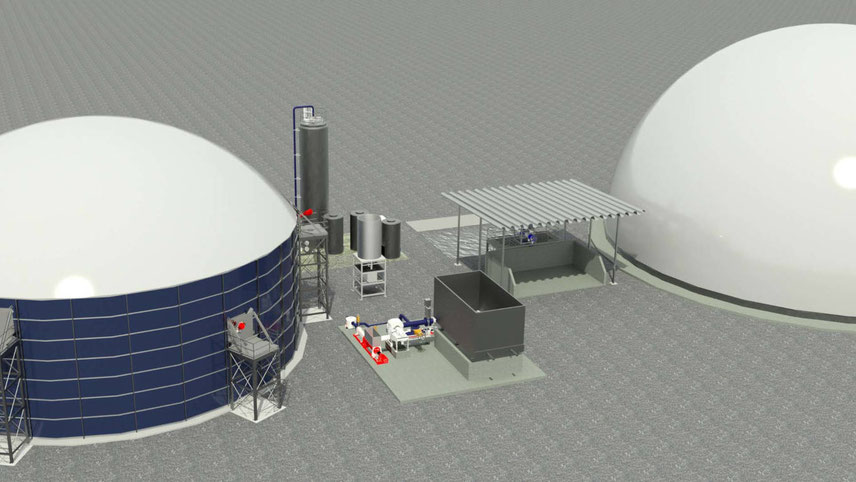

The need for sustainable business practices in the manufacturing space is pressing and organisations are responding by innovating and making dramatic changes to increase their capacities in this area. The textile industry is also spearheading the wave, with more companies opting to go green by establishing circular supply chains that prioritise sustainability from the start of the production. Today, sustainability entails taking swift actions. It is critical to solve present supply chain challenges in order to make it stronger, circular and more sustainable and textile sector must reform operations. How does an enterprise of a large scale and importance to the nation’s economy do this is an often asked question. The good news is that, sector leaders in the textile industry are aggressively decreasing their carbon footprint and serving as role models for others. This includes not only choosing renewable energy sources over conventional ones, but also minimising GHG (greenhouse gas) emissions and water use, etc. A company’s supply chain must be resilient as well as sustainable. In view of increased concerns about climate change and the environment, a circular and sustainable supply chain will need to not only apply rules that benefit society and the environment, but also ensure that resources are available for future. As a result, it is critical for businesses to assess and reconsider their supply chain options, emphasising sustainability, flexibility, agility and efficiency. Let’s look at how the industry might establish circular supply chains and how many organisations have already implemented strategies in this regard. Promoting responsible and sustainable agriculture is a first step in the circular supply chain: Organisations are attempting to integrate sustainability from the ground up, which is an important step in the manufacturing industry. Textile companies are doing everything they can to support ethical farming, from purchasing sustainable cotton to investing in sustainable agriculture technologies and teaching farmers environmentally friendly farming practices. Indian textile manufacturers are also seeking ways and means to reduce waste by optimising their manufacturing processes. Advanced technology and innovation should be at the core: While certain companies have implemented digital platforms to measure, monitor, and report on ESG KPIs towards strengthening accountability across an organisation, others have improved manufacturing capabilities through automation and real-time quality monitoring. Textile companies should also earmark budgets for product innovation to work on sustainability on a continuous basis. Transparency and Trace-ability is important in the modern consumer world: True transparency in businesses means that even the end consumers can view and track the finished product and understand its journey from farm to shelf. Superior blockchain technologies provide traceability right from the original source, thus strengthening the supply chain and integrating sustainability at each step. This is an encouraging move for all, with practices like these bolstering the trust in the industry among consumers, which has a direct impact on growth and revenue.