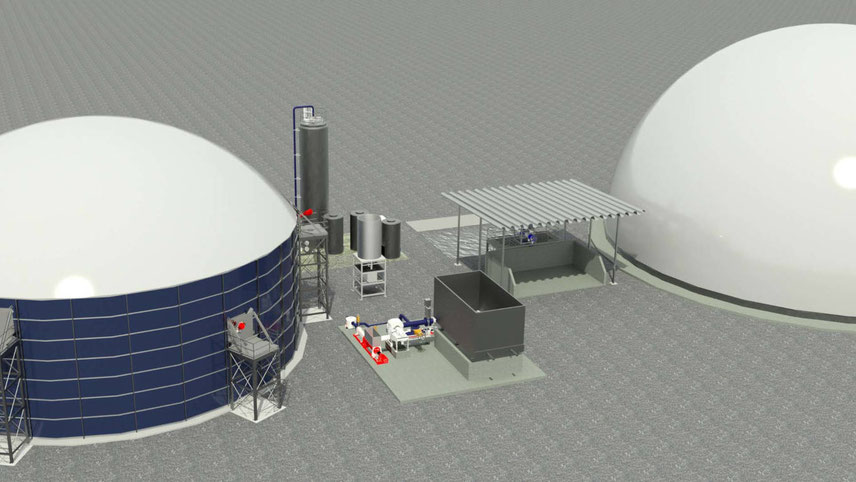

Even as the world unites to fight greenhouse gas emissions and the G7 leaders pledge to achieve net zero emissions by 2050, India is setting its sights on achieving Net Zero by 2070 – a target that demands a radical shift in energy production. Central to this transformation is green hydrogen – the clean fuel of the future, capable of decarbonising industries that have long been dependent on fossil fuels. In this journey, the role of electrolysers, a key device that enables the production of green hydrogen, has become increasingly significant. Today, despite producing 6-7 million tonnes of hydrogen annually, India’s hydrogen supply is predominantly derived from fossil fuels. This is where green hydrogen steps in as a clean, sustainable alternative, created by splitting water into hydrogen and oxygen using electricity from renewable sources like the sun and the wind. As industries shift towards reducing the carbon footprint, electrolysers and the production of green hydrogen are set to drive the future of energy. Leading this revolution in India is Greenzo Energy, a company that has developed a fully indigenous alkaline electrolyser technology specifically designed to cater to India’s unique environmental and industrial needs. The company’s expansive manufacturing facility in Sanand, Gujarat, spanning 20,000 sq m with a capacity of 250 MW per year, was inaugurated during a ground-breaking ceremony, attended by Union Home Minister Amit Shah and Chief Minister Bhupendra Patel in October 2023, with the production slated to commence in December 2024. At the ceremony, Shah addressed the crowd and announced the launch of Greenzo Energy’s facility, emphasising its role in empowering MSME enterprises to produce green hydrogen. He highlighted Prime Minister Narendra Modi’s keen interest in the green hydrogen project and noted that it is in Sanand that the project has officially commenced, marking an inaugural step towards green energy and innovation in India. “There are a few companies worldwide capable of manufacturing electrolysers at scale, with Greenzo Energy being the only company in India with this capability,” explains Sandeep Agarwal, founder and MD, Greenzo Energy. “Unlike foreign manufacturers, whose designs often cater to narrow temperature ranges and limited durability, our electrolysers are engineered to thrive in India’s diverse climates, functioning effectively at 20-60°C and offering a longer lifespan of 20 years," says he. "Our technology employs alkaline electrolysis for hydrogen production and has been the gold standard for over a century. While other electrolysers deliver hydrogen only up to 16 bar, our electrolysers deliver hydrogen at 30 bar, eliminating the need for additional compressors and significantly reducing energy consumption costs – an operational advantage that sets us apart. By strategically prioritising indigenous materials, we have manufactured electrolysers that are not only cost-effective but also uniquely resilient to India’s environmental conditions,”adds Agarwal. The innovation begins For Agarwal, an engineer from IIT Roorkee, the path to Atmanirbhar Bharat transcends mere rhetoric. With over two decades of experience in the energy sector, he recognised early on that India’s energy future hinged on green hydrogen. Before establishing Greenzo Energy, as the founder of Kushal Projects, he had already executed over 300 MW of solar projects across Asia, but when he ventured into green hydrogen a decade ago, the value chain was underdeveloped and the technology itself was still maturing. This prompted him to prioritise R&D, assembling a team of IIT graduates and former NTPC officers. Although their journey was marked by numerous punctures, their perseverance ultimately paid off as they eventually developed a successful prototype in 2022. The electrolyser, the most expensive component of a green hydrogen production facility, accounts for about 70 per cent of the total costs. By developing a cost-effective and indigenous electrolyser, Greenzo has simplified the upstream process and made green hydrogen production more accessible in India.

-

Agarwal: our electrolysers are suitable for Indian conditions; Photo: Sanjay Borade