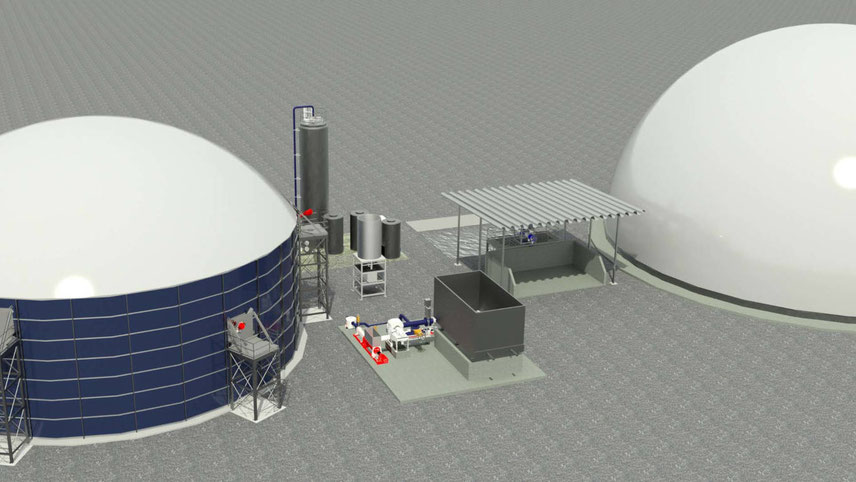

Tata Steel embodies everything which an integrated steel company should do to address the concerns regarding higher emissions of carbon dioxide during the entire steel making cycle. It is striving hard to bring down greenhouse gas emissions, in producing steel and its by-products like slag and coke. It is also taking active steps to reduce consumption of fresh water, recycling industrial water and waste to bring down dust emission as also promote circular carbon economy. The company has been investing in bringing in efficiencies across processes to enable it not just in meeting statutory norms as prescribed in various countries, where it operates but many times going beyond. This is despite its ambitious ongoing expansion plans. The company is planning to increase its production capacity between 35-40 mtpa by 2030. Currently Tata Steel is a multi-location company producing steel in the EU, UK, India and other parts of Asia. Its total production in FY21 was 28.54 mtpa (million tonnes per annum) of which nearly 20 mtpa are produced in India. It is ranked at number 12 amongst global majors, ahead of other Indian companies like SAIL and JSW. The company is a signatory to the Task Force on Climate related financial disclosures (TCFD) for climate change. It has been recognised as the Steel Sustainability Champions for the fourth year in a row in FY21 by World Steel Association. JSW has been conferred this award for the last three years. Going by its ongoing initiatives in reducing carbon footprint, one can see Tata Steel transitioning to a low carbon producer of steel and net zero carbon emitter, well before 2050. Way back in 2012, it had drawn up a new vision plan aimed at reducing carbon dioxide levels to 1.5 tonne per tonne of crude steel (TCS) produced. It had set a goal to reduce the carbon emission by 50 per cent by 2050 from the levels prevailing in 2012. Tata Steel Europe’s carbon emission was 1.90 tonne in FY13. At its Jamshedpur plant the CO2 emitted was 2.52 tonne in FY13. Kalinganagar plant in Odisha was still in the conceptual stage then. In FY21, CO2 emissions were 2.29 tonne per tonne of crude steel produced at its Jamshedpur plant and 2.44 tonnes at its Kalinganagar plant. The near term plan envisaged bringing down CO2 emission intensity at its Indian plants to below 2 tonnes per tonne of steel by 2025, and below 1.8 tonnes by 2030. Dust emission is planned to be brought down to 0.4 kg per TCS. Nearly, 100 per cent solid waste management initiatives have been successfully implemented at both Jamshedpur and Kalinganagar plants. Carbon capture unit Besides bringing down GHG emissions, Tata Steel commissioned a 5 tonnes per day carbon capture project in Jamshedpur in September 2021. The first of its kind in the world in the steel industry, this project aims to capture carbon directly from the blast furnace at Jamshedpur and reuse the same in its onsite, thereby promoting carbon circular economy. Speaking at the plant’s inauguration T.V. Narendran, CEO and MD said, “The operational experience gained from this 5 mtpd carbon capture plant will give us the necessary data to establish larger carbon capture plants in future. As the next step we aim to establish scaled up facilities of CO2 capture integrated with utilisation avenues.”

-

Tata Steel is transitioning to a low carbon producer of steel and net zero carbon emitter, well before 2050