-

Roy Choudhury: instrumental in driving transformation in India

Commenting on the development, Matthias Zachert, CEO & Chairman of the Board of Management of LANXESS AG, says: “India is an important region for us and this strategic milestone reflects our commitment towards meeting the growing demands of our valued customers in the region. The new facility not only amplifies our production capacity but also showcases our faith in the immense potential of the Indian market.”

“We have completed our transformational journey towards becoming a true speciality chemicals company. Amidst this, our India business has done remarkably well, even as the global business has faced multiple headwinds. We are proud of this Indian team. We will continue to invest in India which has grown much faster than any of our other regions,” adds the global CEO, who during his recent visit to India was very impressed to see the development here and was quite excited over upcoming infrastructure investment in the country.

Despite the difficult market scenario in recent years, LANXESS India has continued its growth trajectory. The sales of the Indian operations stood at €315 million in 2023 compared to €208 million in 2020 and €248 million in 2021. Going forward, the company is likely to maintain this momentum. In fact, the Indian business is expected to grow at a CAGR of over 5.9 per cent between 2024-26.

Against this, LANXESS global management believes that overall global sales are likely to increase by around 3.6 per cent. North America at a CAGR of over 1.0 per cent, West Europe at 1.5 per cent, and Japan/Korea at 0.8 per cent are expected to grow at a much slower rate. Even China, with 4.9 per cent, and MEA with 3.7 per cent CAGR growth are likely to lag behind India during the period under review.

As part of its realignment strategy, going forward, LANXESS will focus on the US and Asia markets, while strengthening its presence in Europe. In Asia, India will be its major focus market, likely to drive its overall growth going ahead. This marks a major shift from primarily focussing on China to prioritising India. LANXESS is also strengthening its leading position in medium-sized markets.

“We have successfully completed our transformation journey towards being a complete speciality chemicals company. In the second phase of this journey, we are now in the process of integrating all these businesses in the next couple of years and once that is done, we may think of further ramping up our portfolio, both organically and inorganically. With headwinds in the chemical industry, we are also working on the Excellence Initiative which will be rolled out in a phased manner till the end of Q1 2025. We are going to leverage it to become more efficient for our customers, improve customer management, operational management, logistics, supply chain, procurement, and innovation. The focus of innovation is mostly on the development part, not the research part,” says Namitesh Roy Choudhury, Vice Chairman and Managing Director of LANXESS India Pvt Ltd.

“With all these developments in place, LANXESS India has not only shown resilience but has grown impressively in recent years. India has emerged as a stable growth pillar in spite of global turmoil. Our global management has already taken note of this and today India is one of their focus markets. The commissioning of the new line of Rhenodiv recently at Jhagadia is testimony to our global management showing their commitment to the India business. As a team today, we are proud of these achievements and are all geared up to take this performance to the next level,” adds Roy Choudhury, who is also a member of the LANXESS global leadership team that includes heads of the business units or BUs, heads of global group functions and region heads, in addition to all members of the Management Board. Being at the helm of affairs in India, he has been instrumental in implementing the LANXESS transformation journey in the country.

-

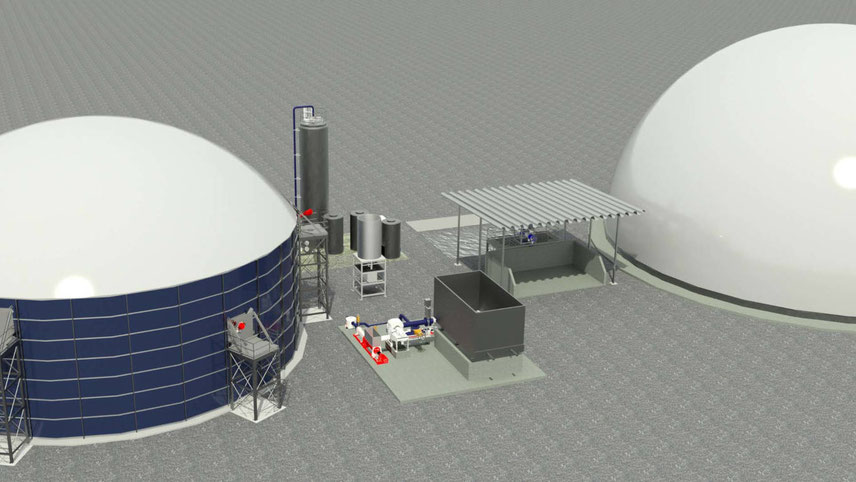

LANXESS has significantly ramped up its facilities at the Jhagadia site

Globally, LANXESS started its journey of shifting to speciality chemicals and divesting basic chemical businesses in 2016 when it acquired the Clean and Disinfect business (comprising various active ingredients and speciality chemicals especially for disinfection and hygiene solutions) of US-based chemicals company Chemours for €210 million. The new business has been integrated into LANXESS’ Material Protection Products business unit

In 2017, the company, in its quest to ramp up its specialty chemicals portfolio, acquired US company Chemtura, one of the world’s leading suppliers of flame retardant and lubricant additives, for an enterprise value of €2.4 billion. The acquisition significantly expanded the company’s additives portfolio and made LANXESS one of the world’s leading players in this growth field, which is one of the most attractive in the specialty chemicals industry. Through this acquisition, LANXESS increased its footprint in North America.

“The acquisition of Chemtura is another major step in our realignment process and a significant milestone in our course of growth. The ‘new’ LANXESS is increasingly taking shape. The expansion of the additives business gives LANXESS an additional strong pillar. In its new set-up and with an even more balanced portfolio, the company will be much more stable and profitable. At the same time, Chemtura considerably strengthens our presence in the North American growth region,” said Zachert, the Chairman of the Board of Management of LANXESS AG during the acquisition.

Consolidating position

In 2018, LANXESS successfully completed the purchase of the phosphorus chemicals business from Belgian chemicals group Solvay, including its US production site in Charleston, South Carolina. In 2020, the company went on to acquire Itibanyl Produtos Especiais Ltda (IPEL), one of Brazil’s leading biocide manufacturers, to strengthen its position as one of the world’s leading manufacturers of antimicrobial active ingredients and formulations.

In 2021, the company made three acquisitions. It expanded its position as one of the world’s leading manufacturers of biocides and antimicrobials by acquiring French company INTACE SAS. The Paris-based biocide company is a manufacturer of specialty fungicides for the packaging industry. This was followed by the acquisition of the French Theseo group, a leading manufacturer of animal health and biosecurity solutions. With this acquisition, LANXESS significantly expanded its portfolio of products for the growth market of animal husbandry, comprising an extensive range of disinfection and hygiene solutions.

In the same year, the company, in one of its largest acquisitions, bought out Emerald Kalama Chemical for €900 million. This US-based specialty chemicals manufacturer was majority-owned by affiliates of private equity firm American Securities LLC.

The acquisition made LANXESS one of the leading providers of products for flavours and fragrances – an area in which the specialty chemicals company expects to see sustained strong growth rates. The substances are used primarily in personal care products, cosmetics, and exclusive fragrances, as well as food and beverages. The product range in the new LANXESS portfolio includes more than 30 aroma chemicals that provide earthy, floral, fruity, spicy and herbal notes.

-

Sriganesh: offering high quality solutions

In July 2022, the German specialty major took over the microbial control business unit of the US group, International Flavors & Fragrances Inc. (IFF). With the closing of the transaction, which was announced in August 2021, LANXESS became one of the world’s largest suppliers of microbial control products. The specialty chemicals company has significantly increased its portfolio of antimicrobial active ingredients and formulations for material protection, preservatives, and disinfectants and is strengthening its global presence, especially in the US. LANXESS paid a preliminary purchase price of around $1.3 billion for the acquisition.

While on the one hand, LANXESS AG started building up its portfolio in specialty chemicals, it also began divesting businesses in basic chemicals. This all started in 2018, when the Cologne-based company sold its remaining 50 per cent interest in the rubber company ARLANXEO to Saudi Aramco for a consideration of around €1.4 billion.

ARLANXEO was founded on 1 April, 2016, as a joint venture of LANXESS and Saudi Aramco. The company produces high-performance rubber for use in, for example, the automotive and tyre industries, the construction industry, and the oil and gas industries. The transfer of the business with synthetic rubber into the joint venture ARLANXEO was the foundation for LANXESS’ strategic realignment. Since then, LANXESS has been focusing on growth in specialty chemicals markets and has made various acquisitions in this area.

Business realignment

In 2020, LANXESS sold its 40 per cent stake in chemical park operator Currenta to Macquarie Infrastructure and Real Assets (MIRA), the world’s largest infrastructure investor, for an equity value of €780 million. Currenta managed and operated infrastructure, energy supply, and other essential services in the chemical parks in the Lower Rhine region and was previously a joint venture between Bayer (60 per cent) and LANXESS (40 per cent).

On 10 January, 2020, LANXESS completed the sale of its chrome chemicals business. The buyer was Brother Enterprises, a Chinese leather chemicals producer. In 2021, it completed the sale of its reverse osmosis membrane business. The business was acquired by French group SUEZ, a world leader in sustainable resource management.

As part of its business realignment, LANXESS also sold its organic leather chemicals business to TFL Ledertechnik GmbH on 1 June, 2021. TFL is a global supplier of leather chemicals and a portfolio company of US investment firm Black Diamond Capital Management, LLC.

In 2022, the company transferred its High Performance Materials (HPM) business unit to an independent legal corporate structure. HPM was one of the leading suppliers of high-performance plastics. These materials are used primarily in the automotive, electrical, and electronics industries.

The German major, post these events, has emerged as a complete specialty chemicals player, even as the integration of new businesses is still in progress. The company has built up a strong portfolio of three segments: Consumer Protection, Specialty Additives, and Advanced Intermediates, catering to a wide range of industries – from energy, natural resources, and industrial applications to automotive, chemicals, construction, nutrition, health, and consumer goods, as well as agriculture and animal health. These three segments have 10 business units or BUs. Under the consumer protection segment, there are four BUs: Flavours & Fragrances, Liquid Purification Technologies, Material Protection Products, and Saltigo.

-

Karaka: driving the new F&F business

With the acquisition of Emerald Kalama Chemical, LANXESS has formed the new BU of Flavours & Fragrances, where it develops and produces flavour and fragrance ingredients, preservatives, and animal nutrition products. “This is a new business unit formed post acquisition. Our F&F substances are found in various everyday consumables, such as cosmetics and personal care products, detergents and cleaning agents, beverages, baked goods, candles, oils, and animal feed. The portfolio also includes specialty chemicals for industrial applications. Industries like pharmaceutical, agrochemical, and construction materials require these for their products,” says Anand Karaka, Senior Sales Director, Head of Sales APAC - Business Unit Flavours & Fragrances, LANXESS India.

LANXESS’ Liquid Purification Technologies business unit is one of the world’s leading manufacturers of ion exchange resins. Its products are used in many industries, including energy generation, the semiconductor and photovoltaic industries, municipal water treatment, biotechnology and pharmaceuticals, the chemical and petrochemical industries, mining and metallurgy, as well as in the production of food and beverages, to name just a few.

The Material Protection Products business unit offers active ingredients, preservatives, and disinfectants. These products protect materials and substances against spoilage by microorganisms such as bacteria, yeasts, moulds, viruses, and algae. The products are used in many industries and applications, such as the construction industry, animal health biosecurity, home and personal care, paints & coatings, wood industries, water and energy sectors, electronics, and beverage technologies.

Under the consumer protection segment, the wholly-owned subsidiary Saltigo is a global company focusing on exclusive synthesis, also known as custom manufacturing. At the company’s German sites in Leverkusen and Dormagen, it produces active ingredients and intermediates, on a contract basis, for the agricultural, pharmaceutical, and fine chemicals industries. In addition to custom manufacturing, it offers a wide range of fine chemicals that are used as intermediates in many industries.

Under the Specialty Additives segment, there are three business units: Lubricant Additives, Polymer Additives, and Rhein Chemie. The Rhein Chemie business unit is the largest supplier of additives for the rubber industry, offering individual and innovative product solutions. These include rubber chemicals, specialty chemicals, and processing aids used to create high-performance rubber products such as profiles, seals, drive belts, and tyres.

A durable car tyre results from a complex manufacturing process in which the tyre is built up from various rubber compounds and reinforcing materials. Rubber is soft and not very durable until vulcanisation. By using rubber chemicals and various fillers, the raw material rubber is turned into a high-performance product. With the selection of the respective rubber type as well as the crosslinking chemicals and additives, the final article obtains the desired technical properties.

“Whether for tyres or technical rubber goods: as a partner to the rubber industry, we offer high-quality solutions – for the development of the compound to the production of the finished component. We supply the rubber industry with a broad portfolio of pre-dispersed chemicals, processing promoters, and vulcanisation and filling activators. In addition, the portfolio also includes anti-sun check waxes, release agents, tyre marking paints, and tyre curing bladders,” says UP Sriganesh, BU Head, Rhein Chemie.

-

Antony: committed to diversity

Comprehensive portfolio

The Lubricant Additives business unit offers a comprehensive product portfolio of lubricants, including additives and additive systems, synthetic base fluids, and ready-to-use lubricants. Similarly, the LANXESS Polymer Additives business unit is one of the world’s leading manufacturers of bromine, bromine derivatives, and phosphorus chemicals. These serve as building blocks for producing complex molecules used in flame retardants, oil production, agrochemicals, pharmaceuticals, fine chemicals, butyl rubber, polymers and biocides, paints & coatings, and colorants for plastics or inkjet printing inks.

Under Advanced Intermediates, there are two business units: Advanced Industrial Intermediates and Inorganic Pigments. High-tech end products require optimised precursors and the addition of the necessary production additives at the right moment. The Advanced Industrial Intermediates business unit produces high-quality basic and fine chemicals for further processing worldwide.

It is divided into business lines and offers a broad product portfolio with a wide range of applications. On the other hand, the Inorganic Pigments business unit brings colour to life, producing inorganic colour pigments used worldwide for colouring in numerous industries such as construction, paints & coatings, and plastics.

The LANXESS Urethane Systems business unit is one of the world’s leading manufacturers in the polyurethane industry. Polyurethanes are versatile plastics or synthetic resins with a certain hardness that can replace rubber or even metal. They are used in almost all industries, including the construction industry, metal processing, the paint and coatings industry, and for tyres and wheels.

LANXESS India is represented through all its 10 business units, operating out of its registered office in Thane, Maharashtra, and a sales office in New Delhi with around 800 employees across locations. The company has manufacturing facilities in India for four of its business units, with manufacturing sites located in Nagda in Madhya Pradesh and Jhagadia in Gujarat.

A greenfield investment of LANXESS, the site in Jhagadia, is one of the company’s large production sites in India. At Jhagadia, the company has production facilities for its three business units: Liquid Purification Technologies, Rhein Chemie, and Material Protection Products. Given its global expertise, the site’s locational advantage and infrastructure, and the positive outlook for the Indian chemical industry, the site serves as a perfect hub to supply customers not only in the rapidly-growing local market but also in the Asia-Pacific region.

The operations in Nagda are part of the Flavours & Fragrances business unit of LANXESS India. The products manufactured at this site are supplied to the domestic market and exported to countries worldwide for a wide range of end applications like epoxy & coatings, flavours & fragrances, personal care, agrochemicals, pharmaceuticals, and dyestuffs, among others.

-

LANXESS India has also implemented advanced technologies and automation systems to boost its capacities

“We have made significant advancements at both our production sites. In Nagda, we enhanced production capabilities in 2024 by installing advanced technologies for better control and energy efficiency, initiated emission and waste reduction projects, and expanded our product portfolio. Meanwhile, in Jhagadia, the expanded Rhenodiv production line, operational since 1 February, 2024, has boosted our production capacity to meet growing market demand. We have also invested in renewable energy projects, adding solar panels and street lights, and expanded rainwater harvesting initiatives to support local water needs,” says Roy Choudhury, who has been executive director of the company since 1 October, 2021, and vice president Industrial & Environmental Affairs for LANXESS India since 2007. He moved to LANXESS India in 2004 after the carve-out from Bayer.

As a responsible company, LANXESS in India has achieved 84 per cent climate neutrality on an annualised basis for scope 1 and scope 2 emissions and significantly reduced emissions at its plants. On the global level, the company aims to completely achieve climate neutrality by 2040.

“Moreover, globally, LANXESS is committed to diversity, aiming for 30 per cent women in management positions by 2030. Gender-sensitive policies, equal pay for work of equal value, and zero tolerance for sexual harassment at the workplace have been implemented. We have created an internal platform called WinX for imparting skills and empowering women to address their concerns. Currently, about 10 per cent of the workforce in India are women. We have identified gender-neutral positions where we can take women based on competencies,” says Sunil Antony, Head, HR, APAC & India, LANXESS.

With all these developments in place, LANXESS in India is today strongly positioned to explore emerging opportunities in the chemicals market. The company has emerged as a complete specialty chemicals organisation by divesting its basic chemical businesses and ramping up its specialty chemicals portfolio. Moving away from basic chemicals and focusing on specialty chemicals, the company is building a robust business model to leverage the non-cyclical nature of the business effectively. Based on all this, LANXESS is now ready to commence its next growth phase in a more determined manner.